|

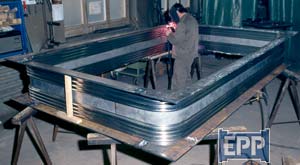

Engineered Piping Products Ltd, can offer a full range of metal expansion joints in cylindrical and rectangular shapes. These metallic expansion joints can be utilised for every application including HVAC, Commercial, Industrial, Petrochemical, Refinery and standard Process and Power plants. Material Ranges which we work with Size range includes cylindrical units up DN14000 and large sizes in rectangular or square joints and all without any welded corners, when you have welded corners this is a weak area which tends to fail due to the high stresses and the hardened welded areas. Our Units are free from all this welded corner problems. See picture below EPP expansion joints are offered with a full range of approvals such as PED/CE, ASME ‘N’, ‘NPT’,’U’ and ‘R’ quality assurance stamps. |

|||||

Expansion Joint Types / Styles

|

Axial Expansion Joints. Axial compression and extension lateral and angular movement can be accommodated. These expansion joints do not restrain the internal pressure thrust. The piping designer must provide the system with separate anchoring and guiding to resist the pressure thrust. Where small thermal movements are involved and proper anchoring and guiding is feasible, a single expansion joint is the most economical installation.

|

|

Tied Axial Expansion Joints, except the overall length and axial movement is restrained by tie rods designed to contain pressure thrust. A tied Axial is usually designed for lateral offset so that the tie rods can remain fully engaged and loaded with the pressure thrust force. A two tie rod design can accept angular deflection in a single plane.

|

|

Universal Expansion Joints consist of two bellows separated by a pipe spool. This configuration accommodates large lateral movements, in addition to axial compression and extension and angular deflection. These expansion joints have no restraints / Tie rods to resist pressure thrust and like the single axial, the piping designer must provide separate anchoring to handle pressure thrust.

|

|

Tied Lateral Expansion Joints contain two bellows separated by a pipe spool and tie rods designed to contain the pressure thrust force. These expansion joints are generally designed to accommodate lateral movement only. A universal expansion joint can be designed to have a very low lateral spring force to minimize forces on adjacent equipment. A two tie rod design can also accept angular deflection in a single plane. The tie rods are usually at or near ambient temperatures and, therefore, do not expand and contract as a function of the temperature of the media within the pipe. As a result, the thermal expansion of the length of pipe between the tie rod end plates is forced into the bellows as an axial movement. The bellows design must accommodate this axial thermal expansion as well as the specified lateral movement. Sometimes a universal expansion joint has a very heavy centre spool that can exert excessive weight on the bellows elements. To protect the bellows elements from excessive lateral loads, a support system such as a slotted hinge can be installed across the individual bellows elements to support the dead weight of the centre spool.

|

|

Hinged / Angular Expansion Joints have a single bellows with overall length restrained by hinge hardware designed to accommodate pressure thrust. A hinged expansion joint allows angular movement in a single plane. A system consisting of two gimbals and a hinge can accommodate very large movements with very low reaction loads on the adjacent equipment. This is a very attractive application for large diameter hot piping systems even if the movements are complex and not in a single plane.

|

|

Double Hinged / Angular Expansion Joints have two bellows separated by a pipe spool with overall length restrained by hinge hardware designed to contain pressure thrust. A hinged universal expansion joint accepts large lateral movements in a single plane with very low spring forces.

|

|

Gimbal Expansion Joints have a single bellows and gimbal hardware designed to resist pressure thrust. The gimbal expansion joint hardware operates like the universal joint on a drive shaft to accommodate angular movements in any plane. A three-hinge system can accommodate very large movements with very low reaction loads on the adjacent equipment. This is a very attractive application for large diameter hot piping systems if the movements are in the same plane.

|

|

Universal Gimbaled Expansion Joints are similar to the hinged universals except that the two expansion joints are gimbal type. The advantage of this arrangement is the ability of the expansion joint to accept large lateral movements and independent angular movements in any plane.

|

Gallery